-

Blended Polyol For Automotive filter -

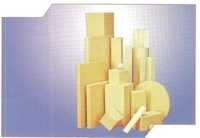

PUF Sheet Slab -

Polyol For Thermoware -

Polyol for ISF -

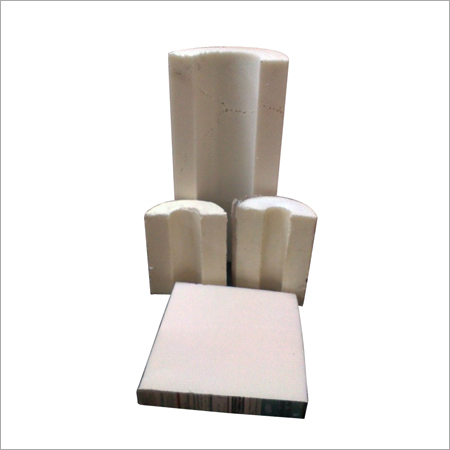

Polyol for Moulded Foam -

Polyurethane Flexible Foam -

Polyurethane Foam -

Polyol For Refrigerator -

PU Leather Wall Panel -

Designer 3D Lather Wall Panels -

PU Decorative Lather Wall Panels -

Wall Panels -

PU 3D Lather Wall Panels -

3D Lather Wall Panels -

Office Furniture Foam Chair Seats -

Furniture Foam Seats -

Four Wheeler Seat -

Automobile Foam Bus Seats -

PU Handle -

PU Chair Handle -

SS Chair Handles -

PU Chair Handle -

Chair Handle -

Pipe Section -

Puff Pipe Section Sheets -

Pipe Sections -

Continuous & Discontinuous panels -

Puff sheet and Pipe section

Royal Industries is an ISO-9001-2008 Certified company was established in 2003. The Company started its industrial operation by blending the polyol used in the rigid/flexible Polyurethane industry. In 2003 the facility was upgraded within house technology for manufacturing both, polyester and polyether based Polyol for Rigid, Flexible (Moulded). This enabled it to offer a consistent quality of Polyol blends to the industry like Panels, Refrigeration, Appliances, Automotive, Furniture and Shoe Sole industries. The present capacity stands at 6000 MT p.a.

Royal Industries has conceived and employed methodologies, beginning with raw material sourcing, product development and end product application that puts its squarely in league with world majors in polyurethane production given the organized nature of these processes to drive the outcomes as expected.

We take every care every step of the way to produce or help you from the end product that precisely correspondence to the required configuration.

Royal Industries success can be attributed to its path breaking Research & Development efforts. Its scientist has indigenously developed various types of Polyol for diverse industries.

Our Products

- Polyster Polyols

A wide range of aliphatic as well as aromatic polyester polyols are manufactured mainly from dibasic acids and diols for varied polyurethane applications. This class of polyols is marketed under the brand name Gepol and Gexter. Even while a large selection is available from our standard grades of polyester polyols, we take pride in taking up development and production of polyester as per our customer's specifications.

- Blended Polyster and Polyether Systems

We consume a majority of our own basic polyurethane raw material to manufacture tailor made formulations for a wide variety of polyurthene applications. Royal Industries expertise lies in manufacturing 'ready to use' systems according to specific requirements and after a careful assessment of process engineering besides physical, chemical and environmental aspects.

Our system product portfolio covers many and varied cellular and non-cellular polyurethane. Royal Industries offers blended polyols under the band names of Gepol with corresponding isocynates (MDI) sourced from outside or with prepolymers and modified isocynates manufactured by us.

This class of polyurethane material from Royal Industries demonstrates its suitability for energy saving applications such as:

- Domestic Refrigerators

- Commercial refrigerating appliances and Cold Rooms

- Sandwich panels for buildings and Telecommunication shelters

- Pipes and chemical storage tanks

- Roof spray

- Electrical and Solar water heaters

- Thermo ware etc.

- Technical Support

The various area of polyurethane usage entails extending quality control to the customer's applications.

It requires factoring in every bit of the technicalities associated with a specific system or an end product requirement, in their respective developments.

While this is effected at the pre-scale stage, technical break up service is at the intermediate disposable of the customer to rectify any lapses or anomalies that might occur in the development process.

Besides technical service Royal Industries also customized development support to develops suitable specific products.

Quality Policy

We adhere to a strict quality policy in our organization. By thoroughly following the quality policy, we ensure the supremacy of our products. Some of the key points of our policy are:

- Source raw materials from trusted vendors

- Streamline all processes

- Inspect each stage of production

- Provide adept facilities for the safety of workers

- Impart regular training to the workers

- Test the final product on various quality parameters.

Some of the quality parameters on which the final product is tested are pH value, purity and stability under atmospheric temperature and pressure. Our various quality control measures provide complete value to the customers, thus exceeding their satisfaction level.

Manufacturing Facility

We have set up a modern and well equipped manufacturing facility to ensure efficient production. Proper care is taken in regards to the type of raw material used, the reaction conditions and the proportions of the initial material, which are responsible for the product's characteristics. Our current monthly production capacity is 250 MT. We also provide customized solutions to our customers according to their varying requirements.

Why Us?

We have successfully gained a strong foot in the industry in a short span of time. We owe this success to the following traits of ours:

- Prime quality of the products

- Competitive pricing policy

- Modern manufacturing facility

- Wide distribution network

- Ethical business policy.

|

ROYAL INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |